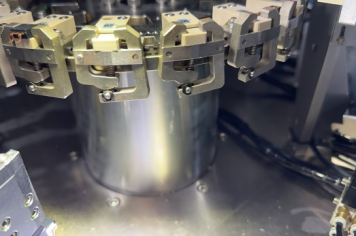

SKD936PLUS Turret Test Handler

SKD936PLUS/SKD936PLUS-C turret test handler for multi-functional test sorting needs, to meet the choice of more stations, flexible material supply with the way to support a variety of flexible configuration of the way out of the material, but also to meet the customer's more categorized and the capacity needs; at the same time take into account the larger size of the package products (TO220/263/247, TO251.), the right-angle clamp test products such as TOLL6R, LFPAK, PPAK8X8, XJ836, TOLL6R, LFPAK, PPAK8X8, XJ836 and other right-angle clamping products).

Products

Semiconductor Field

Test Sorting Equipment

Contact Us

Product Description

SKD936PLUS/SKD936PLUS-C turret test handler for multi-functional test sorting needs, to meet the choice of more stations, flexible material supply with the way to support a variety of flexible configuration of the way out of the material, but also to meet the customer's more categorized and the capacity needs; at the same time take into account the larger size of the package products (TO220/263/247, TO251.), the right-angle clamp test products such as TOLL6R, LFPAK, PPAK8X8, XJ836, TOLL6R, LFPAK, PPAK8X8, XJ836 and other right-angle clamping products).

●Mark Inspection Vision (2D Mark Inspection) recognizes and recodes marks, broken and redundant mark strokes, and marks that are outside of the plastic seal.

●3D5S can detect product size and integrity; it can also detect pin length, standoff height, offsets, pin width and pin spacing.

●In Pocket Vision (In Tape) detects defective products (defects visible to the naked eye) such as broken, contaminated and cracked plastic seals.

●Product transfer: main turret has 36 vacuum pickheads.Sub-turret with clamping mechanism 20 pcs

●Pickhead feature shielding and automatic height correction functions.

●Can be connected to a variety of brands of tester, software independent property rights, the use of key switches, standard keyboard for operation and data input, with workstation interlock function.

●Orientation Aligner: accurate positioning and commutation of the product, positioning tolerance ≤ 0.005mm, directional accuracy up to 0.1 degrees

●No. of testing stations: Up to 8 stations for elastic clamping with high testing accuracy.

●Packaging: TO220, idle UPH ≥ 11k (no testing or testing and marking time ≤ 120ms).

Important parts

|

|

|

| The sub-turret station adopts a large disk surface and multi-station method to improve marking efficiency and take into the large package products. | The testing station on the sub-turret utilizes clamping to meet the testing needs of different large packaged products. | The tube sorting BIN adopts servo motor to control the screw and slider, with accurate positioning, high speed, high efficiency, and high number of tube-sorting. |

Table parameters

| SKD936PLUS | ||

| Suitable Components | TO220/263/247, TO251, TOLL6R, LFPAK, PPAK8X8, etc, and all right angle clamp-testing products | |

| UPH | Max 11,000 (testing time less than 30ms)(pcs/h) | |

| Test station | supports 8-station testing | |

| Contact type | clamp-testing | |

| Classification | 10 tubes in | |

| Onload | Bowl in/ Tube in | |

| Offload | Tape out/Tube out | |

| Stability | MTBA>60min MTTA<3min MTBF>168H | |

| Pressure | 0.4-0.7MPa | |

| Vacuum | >65KPa | |

| Power Source | AC220V / 380V 50/60Hz | |

| Marking Parameters | 10W laser maker:SKDCW10Y-S Minimum letter height:0.3mm Line width:0.045mm-0.06mm;SKDCW10Y-H Minimum letter height:0.2mm Line width:0.02mm-0.03mm | |

| Image Parameters | Camera and resolution: 1.6-megapixel CCD camera, resolution: H1440xV1080 pixels; accuracy: ≤0.015mm/pixel; cycle time: <50ms | |

| Bus Program | High precision, fast speed, open access to all servo parameter settings for easy equipment debugging and monitoring of various MTBA raw data records. Equipment operation logs, alarm codes, and information are permanently stored for data retrieval. | |

| Dimensions | 2251*1205*1900(mm) | |

| Work Stations | 36Work stations(main) + 20Work stations(auxilary) | |

| Important components | imported DDR |

Related products