SKD810H Gravity test Handler

SKD810 H equipment is a fully automatic sorting equipment specially designed for testing TO series packaged power device products. The sorting equipment has multiple test stations in series at normal temperature / high temperature, integrating the functions of high-temperature heating of products, high-temperature testing ( or normal temperature testing ) , laser marking, brush dust removal, and 2D visual inspection .

Products

Semiconductor Field

Test Sorting Equipment

Contact Us

Product Description

SKD810 H equipment is a fully automatic sorting equipment specially designed for testing TO series packaged power device products. The sorting equipment has multiple test stations in series at normal temperature / high temperature, integrating the functions of high-temperature heating of products, high-temperature testing ( or normal temperature testing ) , laser marking, brush dust removal, and 2D visual inspection .

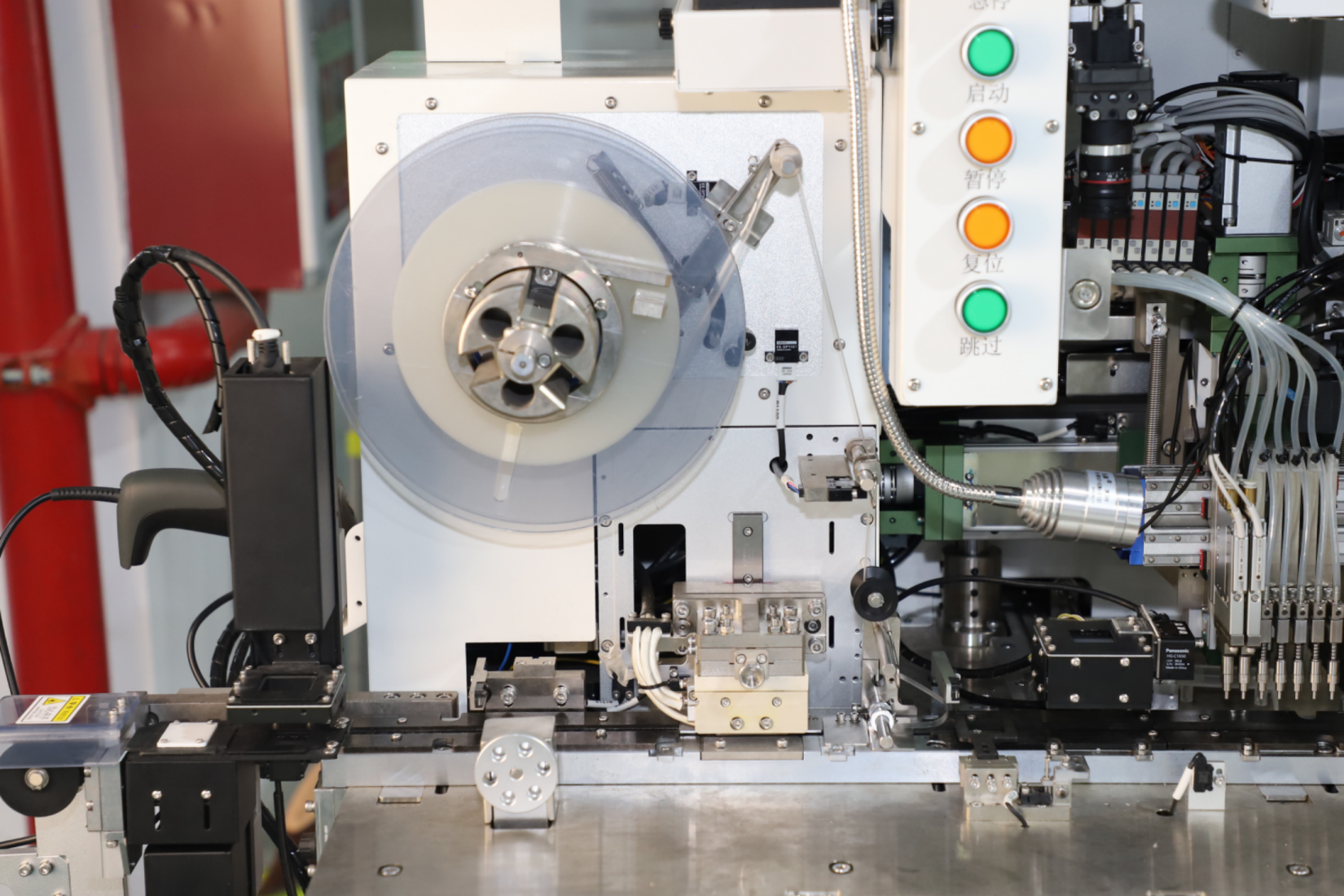

●Loading : Double-tube stack feeding is adopted, and the feeding tubes can be automatically changed (50 pieces can be stacked in a single feeding).

Equipped with normal temperature and high temperature test station mechanism.

●Preheating device: Heating temperature ≤ 175 °, 7 sets of high-efficiency preheating mechanisms (accuracy ±3℃), taking TO-247 as an example, it can preheat 175 materials at the same time, with rapid product cooling performance , and anti-collision at the entrance and exit sensing device.

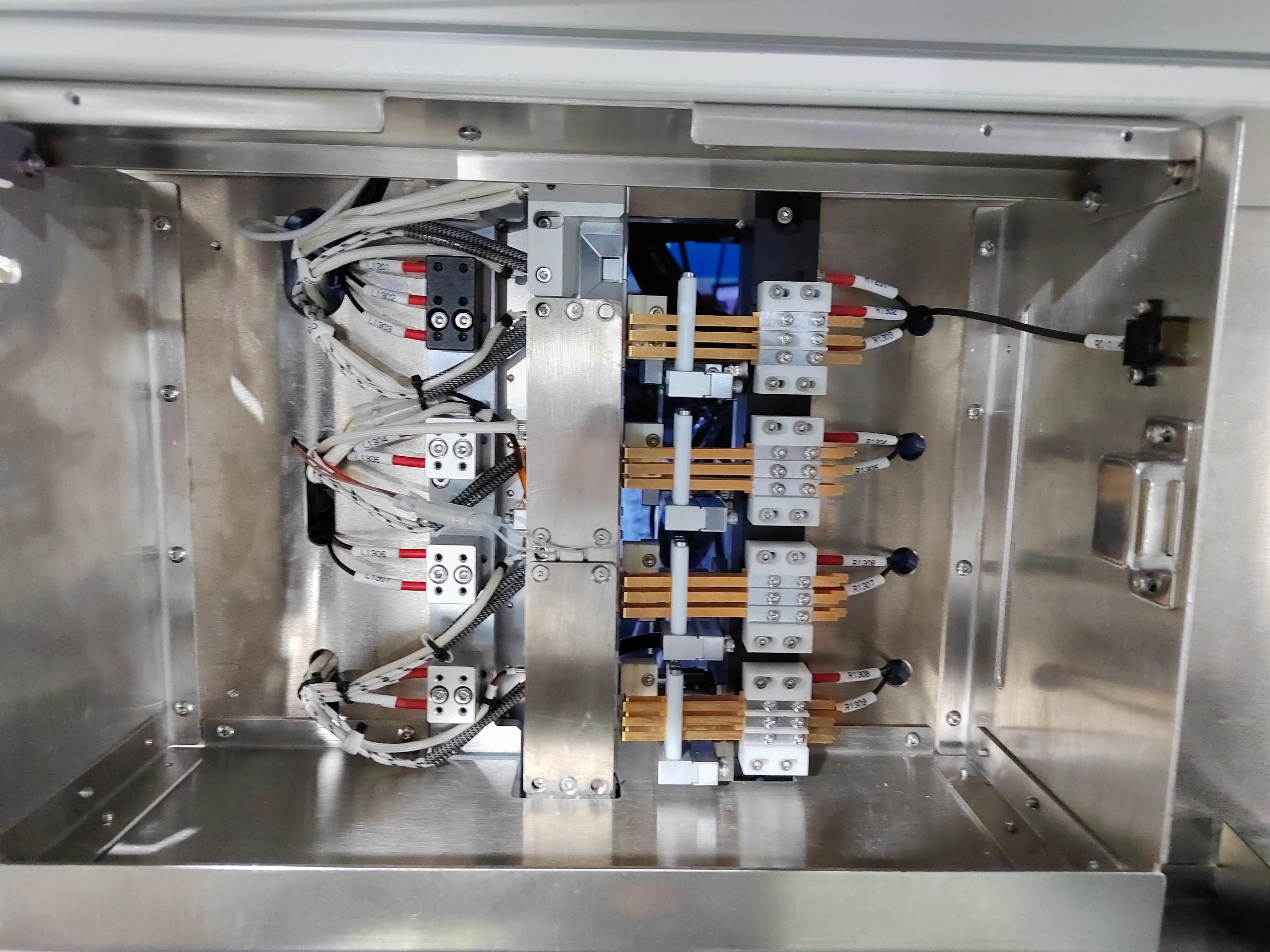

●High-temperature test components: 4 -station high-temperature test, heating temperature ≤ 175 °, test station equipped with heat preservation function (accuracy ± 3 °C).

●Normal temperature test group station : 4 AC / DC test stations.

●Dividing position : driven by a servo motor, the material dividing shuttle cylinder adopts a downward air inlet method, the mechanism is light, and the operation is stable and accurate.

●Offloading: automatic tube out, which can set red and white tubes to effectively distinguish between good and defective products (each classification slot can hold 18 tubes).

●PLC control system, friendly human-equipment interface , the interface can display the product quantity, UPH , fault location, cause, processing method and other functions of each material tube in production in real time.

●Optional work stations: QR code reading station. laser marking station. marking cleaning station. 2D vision station.

Important parts

|

|

|

| High-temperature preheating device and normal temperature test track components; 7 track heating, temperature control accuracy ±3°C, taking TO-247 as an example, it can preheat 175 materials at the same time; equipped with 4 normal temperature test stations. | High-temperature testing facility: It has 4 stations of high-temperature testing facilities, and the high-temperature track has a heat preservation function. | Distribution shuttle and BIN dispensing mechanism: The blocking cylinder adopts the downward air inlet method, which is lightweight and improves performance. The Unloading track adopts an air-cooled heat dissipation device to quickly cool down the product. |

Table parameters

| Suitable Components | TO-220, TO-220F, TO-263, TO-247, TO-3PL, etc |

| UPH | Max 4K |

| High temperaturetesting station | 4 high temperature test Work stations |

| High temperature testtemperature | 25-175°C |

| Test temperature accuracy | ±3°C |

| Normal temperature test station | 4 normal temperature test stations |

| Feed | Automatic tube feeding |

| Discharge | TO-220 series usually has 16 -speed automatic tube rewinding, and TO-247and 3PL usually have 12 -speed automatic tube rewinding |

| Communication Interface | TTL |

| power supply | AC220V±10%/380V,50HZ |

| equipment power | 12.5KW |

| air pressure | 100 L/min,5.5 bar,clean dry air |

| size | 1400*1480*2300mm |

| weight | 750KG |

Related products