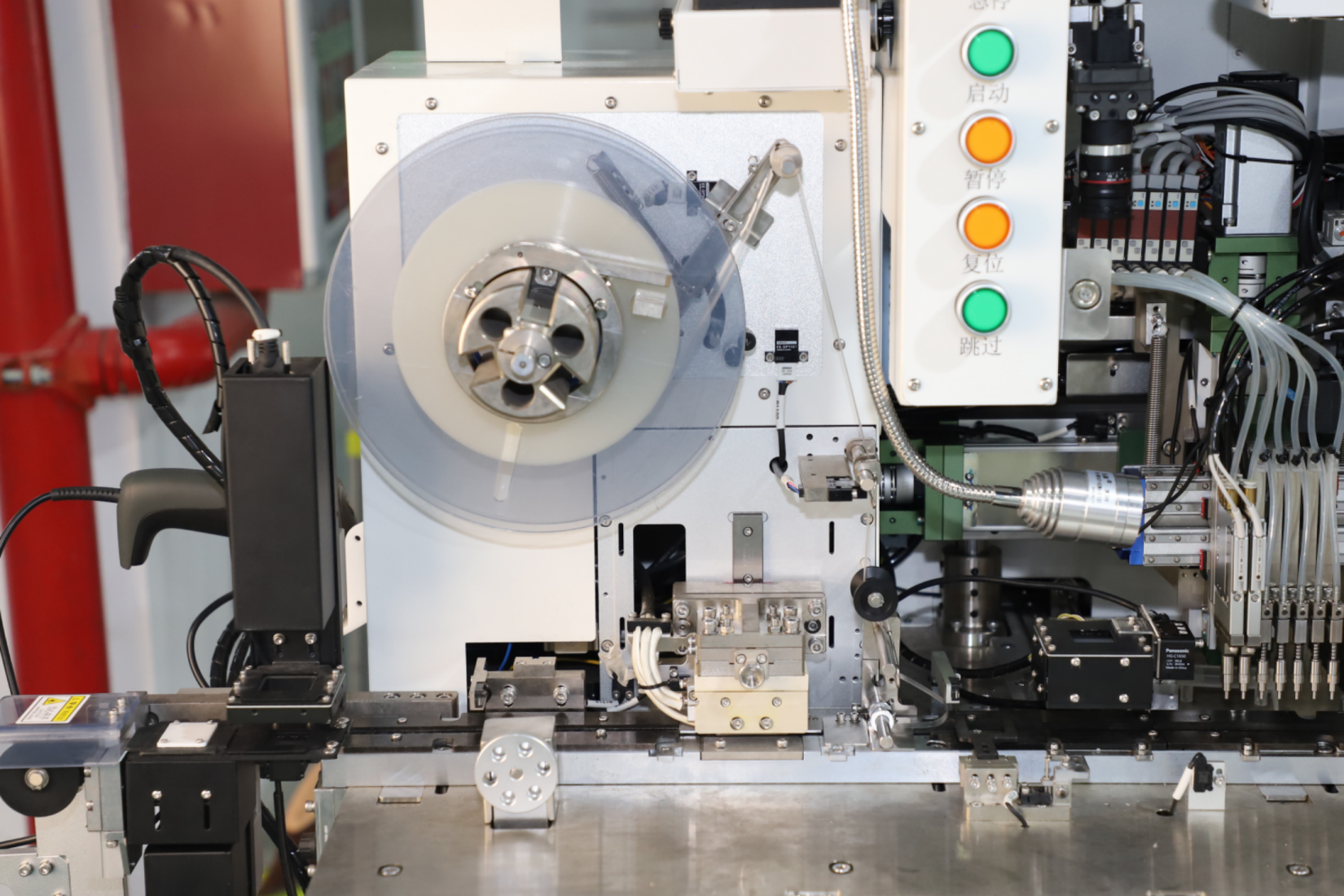

SKD920 Cam-type Dual track Test Handler

SKD920 Cam-type Dual track Test Handler meets high-output demands for products like SMA/B/BF, MBF/S diodes, offering 40-60% faster speed compared to DDR turret test handler under the same testing time. Integrated marking and vision systems provide customers with cost-effective production equipment.

Products

Semiconductor Field

Contact Us

Product Description

SKD920 Cam-type Dual track Test Handler meets high-output demands for products like SMA/B/BF, MBF/S diodes, offering 40-60% faster speed compared to DDR turret test handler under the same testing time. Integrated marking and vision systems provide customers with cost-effective production equipment.

●Unique air distribution design: the air distribution structure of main turret and marking station adopts unique design, with excellent airtight performance and maintenance-free

●Double station design:Each work station (positioning, testing, rotation, marking, 3D5S, sub-Bin) adopts a dual-station design,Equipped with double taping structure, which is twice as efficient as normal(single station workstation) equipment.

●Automatic onload (bowl feeder): double bowl feeder and double straight track feeding, It can stable the performance ,improve equipment input efficiency.

●Main turret :the cam splitter is divided into 24 workstations and assembled with 48 pickheads , which can send the products to each workstation accurately through the adsorption of the pickheads.

●Equipped with 6 stations of elastic pressure contact Kelvin test station, it can complete the repeated test of the products to be taped, and the test accuracy is high.

●Inspection: the equipment is equipped with 6 electrical tests, 1 3D inspection, it has efficient direction discrimination , optical and electrical performance inspection, which greatly improves the excellent and good rate.

●Marking:The marking station uses an independent servo motor for more accurate position control;the material marking surface is at an angle of 60 °to the horizontal plane and is equipped with ash suction components to solve the problem of dust falling on the material surface and provide customers with cleaner marking products.

Important parts

|

|

|

| Double-track loading and offloading at the same time are adopted to improve production efficiency. Monorail production can also be opened, which is efficient and flexible. | The laser station adopts double positioning / double inspection design, which has simple structure and higher efficiency. | The packaging is equipped with 2D detection function to eliminate mixing / warping and reducing labor costs effectively |

Table parameters

| Suitable Components | SMA, SMB, SMC, MBS, MBF, EMB1440, etc |

| UPH | Max 45,000(the test time is less than 60ms)(pcs/h) |

| Test site | Support 6-station testing |

| Contact type | Pop-up type/probe type |

| Classification | 2+2+2+1 |

| Onload | bowl in |

| Offload | tape out |

| stability | TBA>60min MTTA<3min MTBF>168H |

| Pressure | 0.4-0.7MPa |

| Vacuum | ≥65KPa |

| Power | AC220V/380V 50/60Hz |

| Marking parameters | 10w laser marking/20w pulse markingequipment(option); markingrang:110mmx110mm/70mmx70mm,evgravingspeed:~7000mm/s; min characte:0.5\0.3r;outputpower:0-10w/20w(option) |

| lmage parameters | Camera and resolution: 1.6-megapixel CCD camera, resolution H1440xV1080 pixels; accuracy: ≤0.015mm/pixel; cycle time: <50ms |

| Program | high precision,high opensettingofallservo parameters,convenient forequimentdebugging andmonitoring,permanent preservation ofdata such as MTBAvarious original data records,deviceoperation log,sero alarm codeandinformation. |

| Size | 2100*1500*1840(mm) |

| Pickheads | 24workstations(48 Pickheads) |

Related products