Dispenser

● High stability adopts servo+module motion control system+mature software system< br> ● Highly flexible modular design, flexible collocation, and matching with the manufacturing process. Each station is a removable module to facilitate the change of stations<br> ● High precision double CCD 4-point alignment, high precision positioning of vision system, to ensure accurate assembly effect of products<br> ● Fully automatic dispensing with high cost performance, accurate glue quantity control, and accurate visual algorithm improve the yield of dispensing operation; Linear motor driven movement is faster and shortens the idling time< br>

Offset Machine

Products

3C Digital Field

Contact Us

Product Description

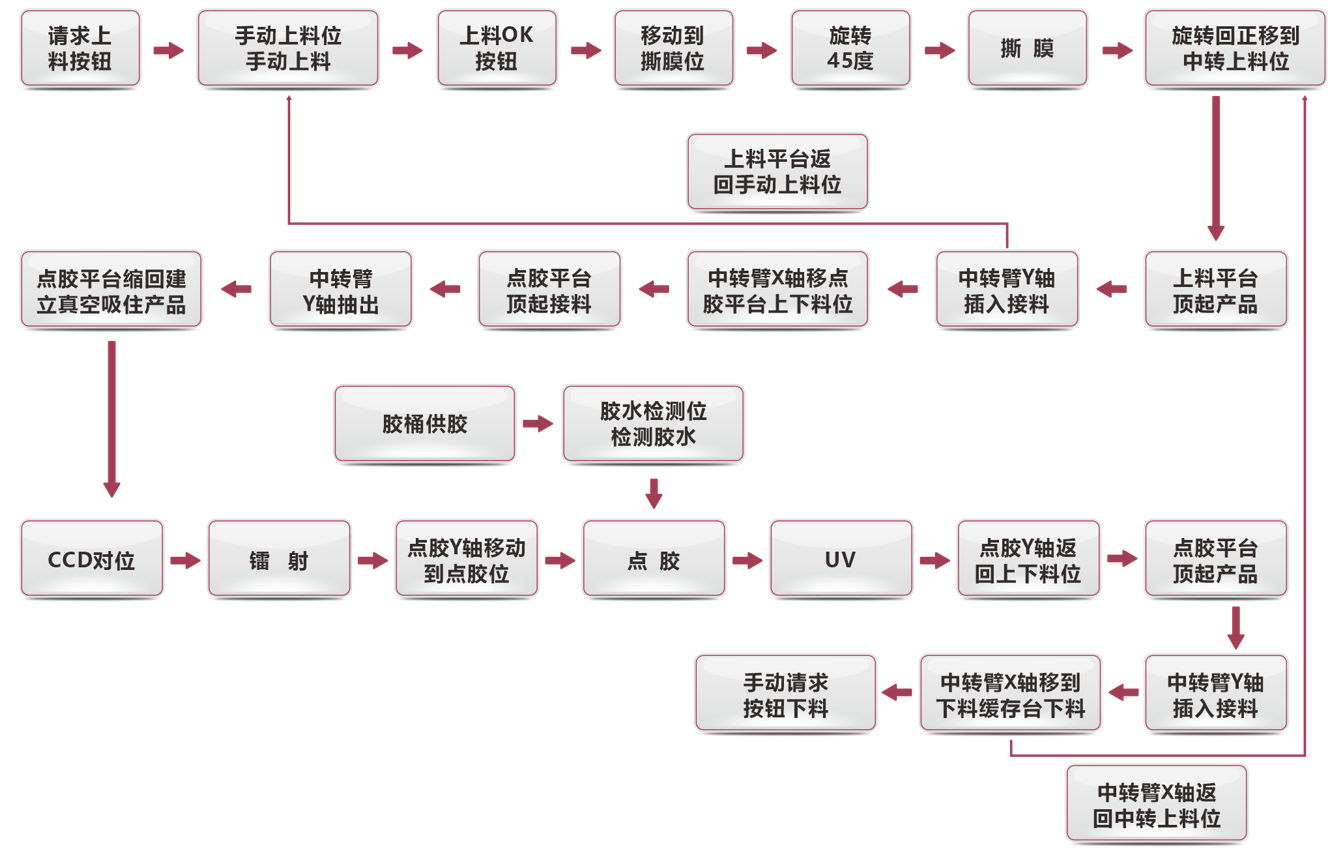

Workflow of YF1191 Dispenser

Technical Parameters of YF1191 Dispenser

| Working state control | 触摸屏 |

|---|---|

| Operating mode | Automatic, manual and idling modes |

| Equipment dimensions |

L* W* H = 2300* 2100 * 2420 (mm) Height includes FFU and four-color lamp |

| Feeding unit | Transmission power: servo+module |

| Precision: 0.005 | |

Flatness: soil 0.01mm |

|

Film tearing unit |

Roller viscosity: according to the material |

| Roller pressure: according to the material | |

| Transfer unit | Transmission power: servo+module |

| Precision: 0.005 | |

| Flatness: soil 0.01mm | |

| CCD unit | Alignment mode: double CCD4 point alignment |

| Single CCD precision: 0.0072mm | |

| CCD resolution: 3840 * 2748 | |

| Field of vision: 26 * 22 | |

| Light source: coaxial |

| Glue spraying unit |

Printing mode: platform mobile, head fixed |

| Repetition precision of Y-axis printing platform: 5um | |

| Heating function: temperature adjustable, maximum 55+1 ℃ | |

| Cleaning: automatic or manual, cleaning sponge or dust-free cloth | |

| UV unit | UV lamp type: halogen lamp, LED compatible |

| Wavelength 365 | |

| Laser unit | Thickness detection method: line scan or point scan |

| Thickness measurement error:<1pm | |

| Secondary distribution | 380v, 50Hz, 40A, 16.5KW in AC 3 |

| 12mm in CDA (CDA blue pipe, HV transparent pipe) | |

| Filter shall be installed on the pipeline connected to CDA of each equipment module | |

safety protection |

Power distribution cabinet leakage, short circuit, overload and other protective devices, protection class IP20 |

| High speed running component terminal safety protection (grating or protective cover) | |

| Four color alarm lamp | |

| Emergency stop button, quantity ≥ 5 | |

| Three level management mode of machine password setting | |

| conserve energy ,reduce emissions | The platform enters standby mode when there is no product flow |

Related products